In a busy textile factory in Bangladesh, Krisno Kumar Das carefully guides fabric into a dyeing machine, satisfied with the knowledge that precious resources and money are no longer swirling down the drain.

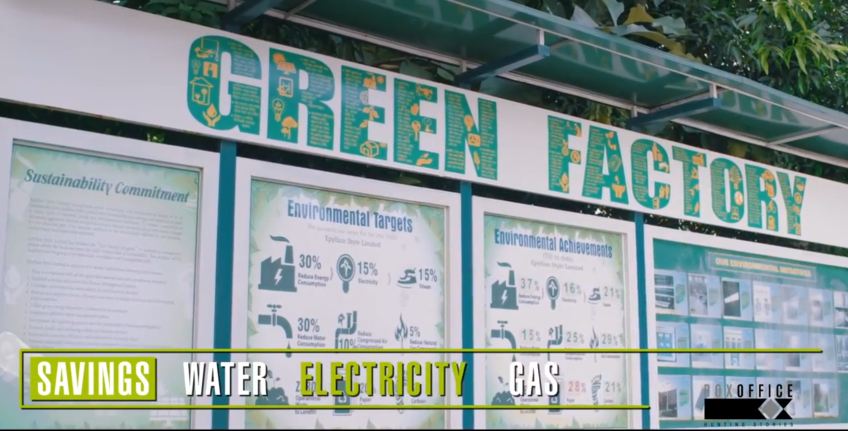

Not long ago, Kumar’s employer, Textown, joined forces with the IFC-led Partnership for Cleaner Textile (PaCT) to switch to more sustainable production methods. This slashed the amount of energy, dye, and chemicals the company used, and cut its water consumption by 11 million liters per year.

It makes sense—environmentally as well as financially, and for individuals as well as companies. “We not only use less water and energy, but we can also do more production work over the same amount of time,” said Kumar. “When we increase overall efficiency, this helps the factory become more profitable, then that helps me when I’m looking for a bonus or other financial benefits.”

Cleaner production has also made Textown more competitive. After switching to sustainable processing solutions, it found greater acceptance as a supplier to brands and retailers focused on the environmental impact of their production and products.